We hear questions about Environmental Product Declarations (EPDs) all the time so it’s clear to us that it’s a rather difficult tool to work with. In this article we'll explain the concept of an EPD and the complexity of its nature. EPDs aren't just black and white. There are pitfalls to navigate around, but once you get the grip of it, you’ll most likely find EPDs to be a brilliant tool in your building and design projects.

In fact, EPDs seem to be the answer to everything now. Everybody wants them! The demand for EPDs is increasing at such speed, that the companies developing the EPDs can’t keep up. It’s become quite a bottleneck.

Since EPDs can be an important tool for architects, designers and specifiers, we’ve asked an EPD expert, Linda Høibye, to give her professional advice on how to work with them. But first, let's get to the bottom of the case.

Architects and designers can benefit in numerous ways by using EPDs in projects. One example is the DGNB certification scheme where EPDs can give extra points.

An EPD is kind of equal to the food declaration you find on the packaging of your everyday food. The EPD shows you what kind of product you're looking at, what the ingredients are, and the environmental footprint related to the product.

The great thing about EPDs is that they give architects, designers, engineers, interior designers and specifiers tangible documentation to compare the environmental impacts of different products within the same product group.

A one-to-one comparison; that’s great, right?

First of all, EPDs are very complex to calculate – and therefore difficult to understand. Secondly, EPDs are only comparable if the same lifecycle scenarios are chosen for the products being compared. Let's explain:

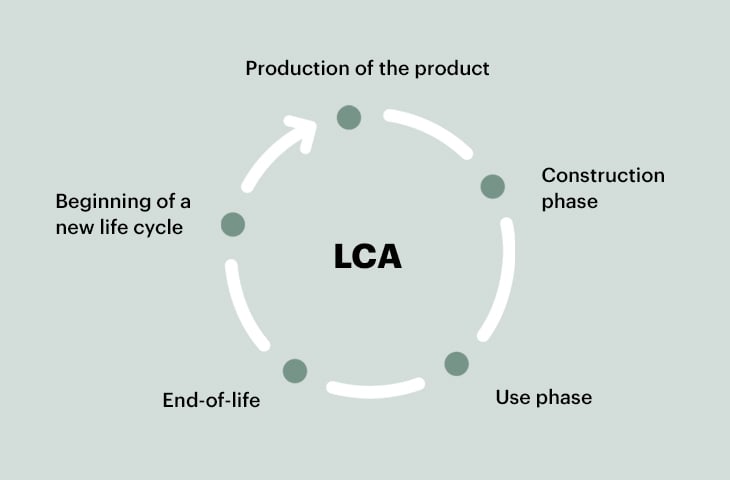

Stage 1: Production of the product

This covers the manufacturing itself, but also extraction of raw materials, collection and processing of these

Stage 2: Construction phase

For building materials, the construction phase, where the product is installed in the building, also counts

Stage 3: Use phase

After installation, monitoring the product being used for a period of time

Stage 4: End-of-life

After use, the product is reused, recycled or disposed of

Stage 5: Beginning of a new life cycle

If the product or product components are recycled or reused, the last stage in the life cycle is the first stage in a new product's life cycle

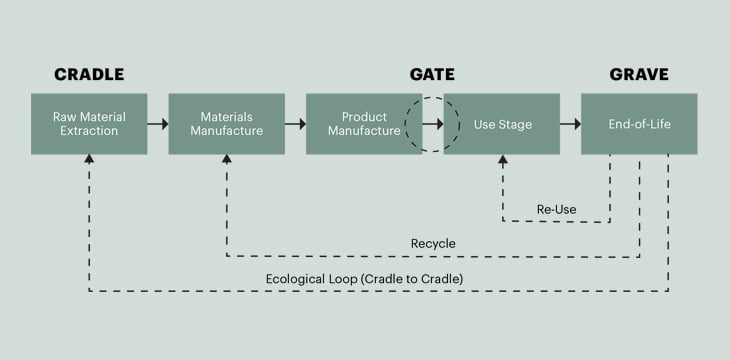

System boundaries define how much or little of the product’s life cycle is considered as part of the assessment. There are many different ways that system boundaries can be defined for the life cycle assessment. Two of the most common ways to look at system boundaries for the life cycle assessment are: cradle-to-gate and cradle-to-grave. The cradle-to-gate life cycle assessment only presents the results from the production stage, while the cradle-to-grave lifecycle assessment represents production, construction, use and end-of-life. This means there are significant differences between these two overall system boundaries.

To be able to compare products, you need to make sure the same system boundary is applied to the products. It makes no sense to compare an EPD from a product that is cradle-to-gate assessed with a product that’s cradle-to-grave assessed. However, even within two cradle-to-grave life cycle assessments there might be differences in how the specific system boundaries have been set by the LCA consultant. So be aware and make sure you read the information on the specific system boundaries in the EPD before applying LCA results.

But that’s not the only thing you need to pay attention to. You also need to understand that the product manufacturer can choose between different end-of-life scenarios when the assessment is made – and that choice has tremendous impact on the final outcome of the life cycle assessment.

Products that are reused or recycled in the end-of-life stage typically have a significantly smaller environmental impact than products that are incinerated after use. That makes it very attractive for manufactures to choose recycling as the end-of-life scenario. Of course, this is only possible if the manufacturer has evidence that recycling takes place, but there’s no rule saying it should happen every time. This means that if there’s a recycling system in place, the manufacturer can choose recycling as end-of-life scenario – even though most products do not get recycled in real life. That leaves a potential false impression of the real environmental impact from the product at the end-of-life stage. So, the EPD verifier should check to ensure that recycling is the real deal. A valid comparison demands understanding of the reality of the situation; is the product really being recycled at the end-of-life stage, or is it incinerated like most waste today?

We agree; it’s all very confusing. That’s why we’ve asked Linda Høibye to give her best advice about EPDs. Linda Høibye is an expert within Life Cycle Assessments and also an approved EPD verifier in EPD Denmark, EPD Norway and EPD International. Linda Høibye has 20 years of experience and has her own company, Life Cycle Assessment Consultancy.

Linda Høibye states that architects, designers and specifiers can benefit in numerous ways by using EPDs in their projects. “One example is the DGNB certification scheme where EPDs can give extra points. Also, the EPDs are used in the LCA-calculations for assessing the potential environmental impact from a building.”

According to Linda Høibye, the EPD provides information on many different things. “The focus in the EPD can vary depending on the reason for using the LCA. It can be the share of recycled material, the end-of-life possibilities for recycling, the absence of hazardous substances in the product, the carbon footprint etc.

Don’t focus solely on greenhouse gasses - the other impact categories can be just as important.

"It’s also important to look for the main assumptions applied when developing the EPD, as these assumptions can affect the results significantly” she explains.

But how can you know if the assumptions are correct; for example, the end-of life scenario chosen? “The main assumptions about the scenarios applied must be included in the EPD. So, the user of the EPD must check if the applied end-of-life scenario matches the actual situation where the product is disposed of” Linda Høibye says.

A big thank you to Linda Høibye for teaching us a little more about EPDs!

EPDs are really complex to work with. It’s a jungle of information and data analysis that takes in-depth knowledge to understand. My best advice is to spend time learning how to use EPDs. You’ll get wiser the more time you invest in trying to understand! And if a story sounds too good to be true, do yourself a favour and ask for more information, especially about the system boundaries or chosen end-of-life scenario. If you still don’t get it, there are plenty of experts and consultants available who can help.

Remember, EPDs can be a one-to-one comparison of similar products. If they’re used the right way, they’re a tremendously important tool to help choose the right solutions for your specific building project.

Are you looking for EPDs on our carpets? They can be downloaded directly from our website. Just find your favorite carpet and click at “Specifications” to get all the info you need. You can also download all the other certificates and declarations we’ve got on each carpet. If you have other requests, please reach out to your local consultant who’s only a click or call away. We can’t wait to hear from you!

Design inspiration delivered straight to you